Metabolomics and Cultivated Meat: Enhancing Nutrition and Taste Profiles

This article was sponsored by Human Metabolome Technologies.

Following regulatory approvals in Singapore and the United States, more cellular agriculture companies are working to bring their cultivated meat products to market worldwide.

As more cultivated meat companies look to scale production and come to market, it will be important for startups to look at the nutritional profiles of their developing products. As recent surveys suggest, consumers may be more open to purchasing and trying these novel food products with taste and nutritional profiles on par with conventional meat and seafood.

According to Dr. Alexander Buko, Vice President of Human Metabolome Technologies (HMT), metabolomic studies can offer an important way to help cultivated meat and seafood companies move forward to enhance the taste and nutritional value of their products.

Having worked with different alternative protein companies, including cultivated meat and seafood producers, Buko identifies how metabolomics can help the field achieve its goals of becoming part of a sustainable future food system.

Metabolomics and Our Food System

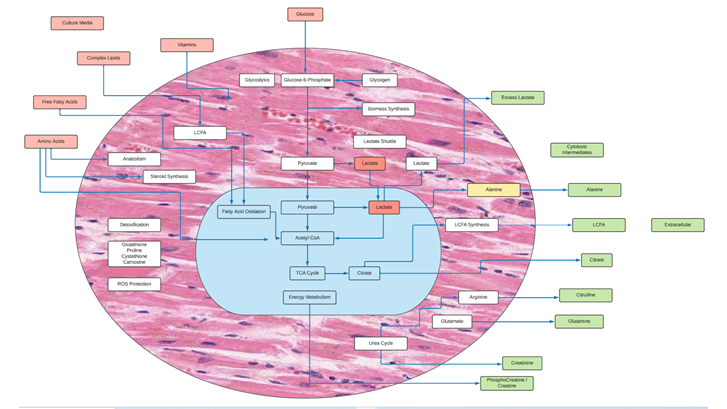

According to Buko, metabolomics is the field of measuring small metabolites and can have a range of applications in understanding the biochemistry of cell-cultured food products.

“Essentially, metabolomics is the measurement of small organic molecules that are loosely defined as under 1500 in mass, so it does not include small metals and inorganic compounds or large biomolecules like polysaccharides, proteins, and DNA.

“Instead, metabolites include amino acids, sugars, nucleic acids, fatty acids, bile acids, steroids, vitamins, phytochemicals, and antioxidants."

With an extensive background in metabolomics, Buko brought his experience in the field to his current position. “HMT is a global metabolomics CRO (contract research organization). We have been in the business for over 20 years, with our headquarters in Tokyo, Japan, and our global office in Boston, Massachusetts, where I operate.

“I am the Vice President of HMT’s global Boston office, and I have been at HMT for the past nine years, where I spend most of my time in sales and analyzing data for my clients.”

Beyond medical applications, Buko shared that metabolomics has a range of applications in our food system, including in developing cell-cultured foods.

“From medicine to food and agriculture to cosmeceuticals, metabolomics is used for understanding the biochemistry of cells and biological processes, composition of taste, nutrient content, bioprocessing, medical research, and more.

“Metabolomics is currently being used to measure nutritional content during product development, comparing cell-derived compositions to natural product nutritional compositions. For bioreactors and fermenters, metabolomics can be used to monitor feed supply, amino acid flux, and other essential metabolites to ensure biomass generation.

“More and more metabolomics is being used to develop production yields and product composition. A newer area is using metabolomics to create a tastant profile.”

Metabolomics and the Cell Culture Media Formulation

The cell culture media formulation is an essential component of producing cultivated meat. From growth factors to vitamins and minerals, the cell culture media provides all the nutrients the animal cells may need to replicate or differentiate into another cell type to become a cell-cultured meat product.

According to Buko, considering that the cell culture media formulation is what the cells are consuming, the cell culture media plays an essential role in how the cells grow. “The cell culture media acts as a nutrient source for the growing cells and an avenue to remove toxins, ammonia, and other extracellular components.

“Therefore, monitoring the cell culture media provides insights into the essential nutrient flux necessary for growth but also visualization of the osmotic and oxidative stress indicators that can slow or limit cell growth.”

Considering the challenges in ensuring that cells grow consistently to produce cultured meat, Buko describes how metabolomic studies can help companies in the field determine how to optimize cell growth.

“There can be several reasons for a lack of biomass growth, from nutrient depletion or the lack of essential cofactors and minerals to high concentrations of free radicals or high ammonia or other toxins.

“Obtaining metabolomic profiles within a well-planned experiment can aid in determining root causes and thereby provide solutions to enable optimum cell growth and product profile.”

Considering that companies are currently focusing on developing their own formulations in-house, Buko describes it as challenging to find case studies of metabolomics studies revolving around cell-based meat.

“Case studies are hard to find in the literature for two reasons. One is just intellectual property; formulations that enable growing beef, seafood, or poultry cells are well kept with each company’s patent protection.

“The second is that optimization can be very specific to a lab's specific cell lines and existing conditions. Therefore, one solution may not fit all. For example, adding succinate or 2-OG may stimulate growth for one condition but not others. In another case, ammonia build-up may be a limiting factor [for cell growth].”

Metabolomics and Cultivated Meat Nutritional and Taste Profiles

Considering the field’s interest in improving the nutritional and taste profile of their cultivated meat and seafood products, Buko identifies how metabolomic studies can help companies recognize the nutrients required for their cells and, ultimately, their final meat products through cell culture media formulation.

“Nutrients fall under two basic categories: those essential for cell growth and those essential for food profile.

“Nutrients are, of course, essential for growth and the composition of the final product. Typically, we find either specific nutrient depletion or the build-up of toxins that limit growth or alter product composition. By monitoring the cell culture media, we can get a handle on the biology of these cells or co-cultures.

“Taste, of course, would require in-house and beta testing to obtain the full taste experience. However, a tastant profile can provide data on how taste profiles can change with product development and identify specific metabolites that may contribute to an undesirable trait, such as bitterness.

“For example, one of our clients had an unusually high bitter product in development. A metabolomic profile of the cell paste showed extremely high levels of citrate. Citrate, however, as free acid, would most likely contribute to an acidic or sour taste.

“However, magnesium citrate is bitter. Therefore, the inference is that this preparation contained high levels of magnesium in preparations that were already high in citrate and malate, both of which are cationic chelators.”

In terms of which metabolites are essential for the taste of meat and seafood products, Buko describes how each type of meat and seafood consists of a unique combination of metabolites that companies in the field will need to match, if not improve.

“Each meat product, whether it is beef, shellfish, chicken or other seafood, has a unique fingerprint of nutritional, functional, tastant, and structural metabolites that all together make each special.

“To identify the specific metabolites that contribute to a product, first testing the fresh [conventional] products would be the best place to start and compare. If substantive ingredients are missing or low yield, or if there is an overabundance of other materials, then options [for cultivated meat producers] include modification of the cells, modification of cell conditions, or adding ingredients to a final product.

“In addition, I would like to add that, to best match the profile of a [cultivated meat] product to the wildtype meat, it is best to use the same technologies instead of just relying on literature that may have used a variety of technologies and protocols.”

Scaling the Future of Cultivated Meat: The Role of Metabolomics

As companies work through scaling their production processes to commercialize, Buko shared how he understands the challenges of scaling up the production of cell cultures and the role that metabolomics can play in supporting companies.

“Scale-up is something I am very familiar with, having worked in pharma for 28 years. The issues with small molecule or biologics scale-up are like working with meat cell cultures. Scale-up can produce several issues, some of which we have already noted, such as lack of sufficient mass production or undesirable taste.

“In addition to lack of proper nutrients for growth, the increases in free radical damage and high amounts of accumulated ammonia can slow or stop biomass production or disrupt the desirable product profile. Each issue would require unique solutions to remove radicals, peroxides, ammonia, and toxins, or increase specific nutrient content.”

As companies scale production, Buko indicated that companies do not need to reach a specific scale or capacity before conducting metabolomic studies. “There is no specific time to introduce metabolomics into the workflow.

“In general, once problems start to become unsolvable, we can help design a time course study to seek a root cause and provide solutions to enhance biomass growth, alter nutrient composition, or improve its taste profile.

“Alternatively, a company can be progressive and begin monitoring metabolites early on before problems occur and then be able to respond faster, saving time and money.”

Metabolomics and the Future of Food

In a recent European survey by a team including the nonprofit ProVeg International, the audience expressed they were open to alternatives to conventional meat and seafood if the novel food products matched the taste and price of conventional meat and seafood.

While scaling production may be able to address the price aspects of cell-cultured meat products in the future, Buko outlines how metabolomic studies can play a valuable role in improving the taste and nutritional profile of these cell-cultured meat products.

“One key [for a successful launch] is presenting products that are indistinguishable in taste, texture, and nutritional content [as conventional meat and seafood]. While some consumers will tolerate taste and texture differences, a significant commercial market requires higher standards.

“Alternative foods will need to demonstrate their products' equivalency to [conventional meat and seafood] products. Metabolomics can help with product production, profile, and taste and provide data for public distribution and awareness.

“A nutrient or metabolic profile can help companies demonstrate equivalency to the conventional meat – proving with data to consumers that they are getting similar or better vitamin content, more antioxidants, higher protein, or lower cholesterol in their alternative product while providing a similar or better texture and taste profile.”

This article was sponsored by Human Metabolome Technologies. For more information about Human Metabolome Technologies, please visit their website (en.humanmetabolome.com) to learn more or contact Dr. Alex Buko or Gina Johnson.

Gina.Johnson@humanmetabolome.com

Stay connected with CellAgri

Join our mailing list to receive the latest news and updates weekly from the cellular agriculture industry. Your information will not be shared.