Cellular Agriculture in Germany: A Landscape Summary

This article was written by and contributed by the Cellular Agriculture Germany team. Note: opinions expressed by CellAgri contributors are their own.

Cellular agriculture (cellag) products are on the market in Singapore from the end of 2020. We see the launch of precision fermentation products in the USA or the US approval for cultured meat in June 2023.

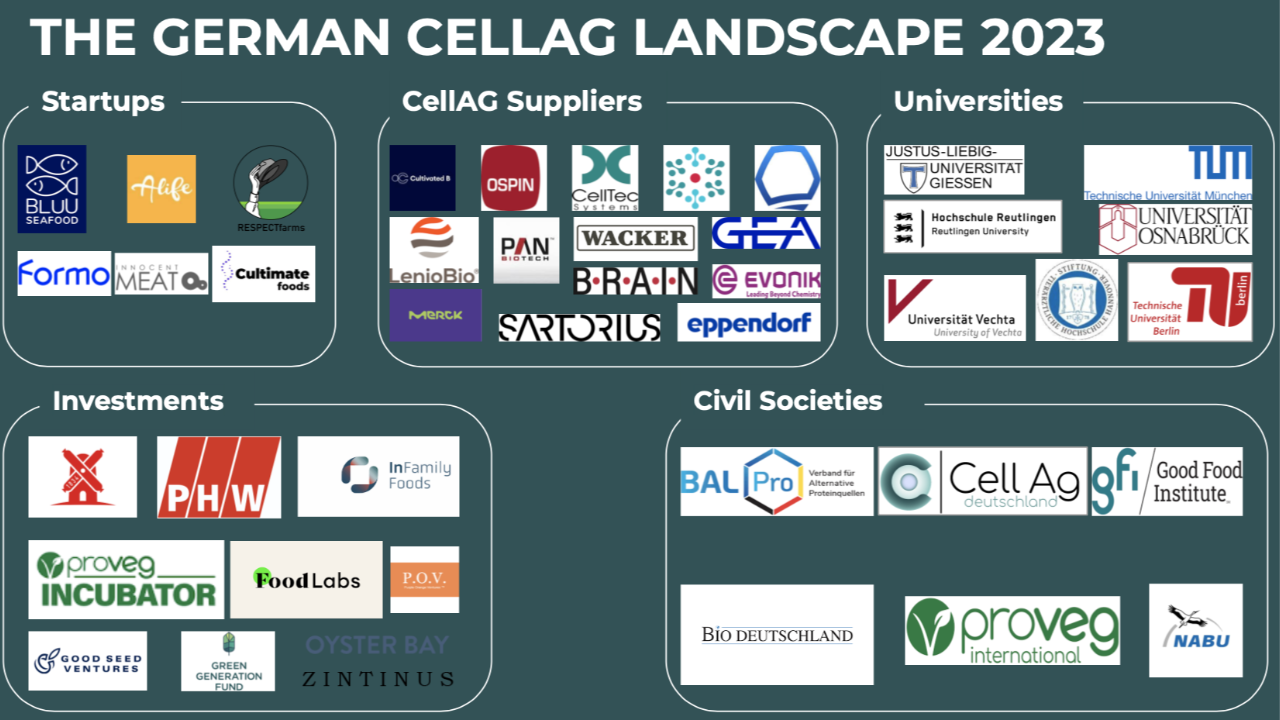

Where does Europe position itself in the cellag industry? This article will focus on Germany and covers startups with technological advancements, investments in Germany, the political landscape, German Universities, and societal organizations providing support for cellag.

Corporate and Technological Advancements in Germany

Startups

Even though there are exciting start-ups popping up in Germany, it is important to note that the overall amount of German start-ups is scarce in comparison to other countries. There is unique potential in Germany, especially for other industries such as the German pharma industry to act as a future supplier along the value chain. For a German future-proof ecosystem to flourish, a catch up is still needed. In the following, you can see the main players in Germany for cultivated fish, cultivated meat, and precision fermentation. We didn’t fully exclude cellag associated players working more broadly on fermentation, as they use similar techniques as the cellag equivalents.

Starting with fish, Bluu Seafood found its niche in cultivating this product, providing arguments of why this process may be easier to conduct due to less complex conditions necessary for fish cells. Their aim is simple and clear: “Cultivated Seafood Made From Fish Cells. Tastier, Healthier And More Sustainable.” Bluu was founded in 2020 in Berlin and received € 7.2 million of funding from 7 investors in the seed round. At the end of June 2023, Bluu Seafood raised € 16 million in Series A funding.

Bluu Seafoods' cell-cultured fish balls

Bluu Seafoods' cell-cultured fish balls

Focusing on precision fermentation, Formo, formerly known as Legendairy Foods, has been around since 2018 with headquarters in Berlin. The company focuses on manufacturing cheese using precision fermented milk protein. Formo thus develops animal-free dairy products to bring the next generation of sustainable, healthy, and equitable dairy products to consumers. They have overall received € 54.3 million from 13 investors.

Formo cell-cultured dairy cheese platter

Formo cell-cultured dairy cheese platter

Moving to the category of cultivated meat, the German landscape shows more players.

Innocent Meat, based in Rostock and using research departments of the University of Rostock, works towards an end-to-end system for conventional meat producers in cultivated meat. Together with the university, Innocent Meat received a federal grant of approximately € 500,000 to “develop a scalable and cost-effective electrospinning method to produce sophisticated scaffolds that enhance cell proliferation and differentiation, and mouth feeling.” The contribution to scaffold research supports a big step within the cellag technology to come one step closer to a credible product. Innocent Meat was created in 2020 and has been funded by 2 investors: Genius Venture Capital & Big Ideas Ventures in a pre-seed round.

RESPECTfarms with activities in Germany, the Netherlands, Belgium, and Switzerland, focuses on the other hand on decentralizing the cultured meat production. They act as a system integrator between the conventional agriculture industry and the cellular agriculture sector, to create a diversified or new business model for farming in this field. They are funded by the European Union and industry partners (around 1 Mio. €) for a Proof of Concept for cultivated meat farms. Results for the Proof of Concept are expected by mid 2024 and a first pilot farm in 2025.

Cultimate Foods from Berlin started to focus on cultivated fat in 2021, having received 700,000 € from 4 investors in their seed round. Their aim is to supply the cultured meat sector with cultivated fat to enhance the flavor and credibility of products.

Alife Foods from Leipzig is a product-oriented consumer-first startup in cultivated meat. Their aim is to offer various meat products, as a middleman between producers of cultured meat, industry organisations, food retail and consumers. They work on the product “schnitzel”, harvesting myosatellite and muscle cells from cows to nurture them with plant-based growth media. For the final product, cells are combined with wheat protein, panade of wheat flour and vegetable oil, and methylcellulose. Alife Foods was founded in 2019.

Cellag Suppliers

The second largest German meat company InFamily Foods extended its portfolio to include a B2B platform, The Cultivated B, for cultivated meat, precision fermentation and bioreactors. With investments in the triple-digit million-euro range, it runs several research labs.

The Cultivated B team during the opening of its facility in Ontario, Canada

The Cultivated B team during the opening of its facility in Ontario, Canada

Rather focusing on the process, OSPIN is a company founded in Berlin in 2014. They provide support in the cellag sector by automating and digitizing bioprocesses through Internet of Things (IoT) solutions and consulting.

2022 was also the birth year of Celltec Systems, a biotechnology company as a spin-off from Frauenhofer institute and the University of Lübeck. CellTec Systems GmbH researches in the field of industrial cell technology to innovate processes for mass propagation for the production of food, diagnostics, test systems and other consumer goods. They aim to open up a new sustainable source of raw materials for various industrial sectors with the industrial use of renewable cell cultures.

DenovoMATRIX, founded in 2018 in Dresden, started out with the development and manufacturing of biomimetic coatings for the cultivation of human stem cells. Currently, they are designing and producing biomaterials which enable cell manufacturing in higher quality, quantity and safety - a process that supports future progress in the cellag sector.

As one of the leading suppliers to the biopharmaceutical industry in Germany, Merck has extensive knowledge in cell culture media and bioprocessing technologies. The company realizes their role in the emerging cultured meat industry and aims to become a technology provider to it. They state to involve themselves from R&D to efficient scale-up of production through partnering with companies dedicated to the commercialization of cultivated meat. They partnered with Aleph Farms to work on fermentation-based growth medium proteins in order to eliminate FBS from the process of nurturing cultivated meat products and also to reduce high costs in the making of cultivated meat.

Aleph Farms also partnered with Wacker, a chemical manufacturing company based in Munich. The non-exclusive collaboration’s goal is similar to Mercks, aiming to provide essential proteins for cell culture media to reduce costs and optimize the production of cultured meat. These proteins are currently not available on the market in large quantities and represent one of the most significant cost factors in the large-scale production of cell cultured meat. Aleph Farms states to couple their scientific expertise with Wacker’s vast experience due to more than 20 years of protein production to produce proteins in the quantity, quality and at the cost necessary to achieve Aleph Farms' ambitious goal of cost parity with conventional meat. Wacker is focusing on fermentation to produce cell-culture proteins for the use in foods, which have the same composition as proteins produced in animal bodies. Similar production processes are already being used to manufacture enzymes for food processing.

GEA is a company for food processing technology. Apart from other services and sectors, they provide the precision fermentation and cultivated meat sector with bioreactors/fermenters.

Sartorius is one of the most known companies in the industry for reactor solutions. Apart from that, they act as a supplier in numerous other areas such as in cell culture media, lab filtration and purification or in cell analysis.

BRAIN BioTech is a specialist in industrial biotechnology and aims at the acceleration of a biobased and, therefore, more sustainable future. Working on growth factors since 1993, BRAIN develops recombinant proteins for the cellag industry, also for German cellag companies.

Evonik is one of the world’s leading specialty chemical companies. They claim to offer high quality cell culture solutions to the pharma industry, but also biotech companies to improve cell culture performance. The ingredients are animal-free, ready for commercial scale and customizable to specific needs.

Eppendorf is a company in life sciences and develops and distributes systems for labs worldwide. Their products range from pipettes, dispensers, centrifuges and mixers, to ultra-low temperature freezers, fermenters and bioreactors.

Pan Biotech (and sister company PAN Foodtech) provides solutions in bioreactors, cell processing or serum-free and cost-effective growth factors. As part of the German cultivated meat consortium CellZero Meat, they further support the advancement of the German ecosystem.

LenioBio is a protein expression platform company that aims at advancing transformative technology to discover, develop and scale proteins, unconstrained by any cell limitations. LenioBio established a legal entity in Germany in 2016 and acts as a protein supplier for the industry. They also joined the community of Cellular Agriculture Netherlands to develop a Dutch ecosystem in cellag.

Tälist is a talent solution platform for the alternative protein industry, including cellag, and connects businesses to talent around the world. They also just launched their impact calculator where professionals can calculate their impact in the alternative protein industry.

More organizations to support or accelerate the industry are projects such as Food Campus Berlin or Future Food Campus Hamburg.

Cellag associates

The line between ‘cellag and not cellag’ technology is fine and the definitions of cellag can be perceived in a more strict or broader sense. In the following, we present some cellag associated startups that can be connected to the cellag space but oftentimes use a different approach towards delicious foods.

Mushlabs from Hamburg uses biomass fermentation to create the next generation of sustainable foods from the roots of mushrooms. The mushroom cells are fed with side streams of agro- and food industries to remain sustainable. Fermentation takes place in a controlled bioreactor environment to multiply and create alternative protein products. Bosque Foods used the Mycelium fungi to strive for a better-than-meat replacement. The company is based in Berlin with an additional location in New York. Kynda enables their partners to produce mycelium in-house using their accessible biotechnology. Cambrium is a biotech company using microbes as cell factories to produce their products, proteins. Their product portfolio includes animal-free collagen.

Investments in Germany

Private

According to analyses of the Good Food Institute (GFI), worldwide investments into cellag could in recent years nearly catch up to the ones of plant-based. In 2022, plant-based companies gained 1,188 million US dollars, companies in cultivation 896 million US dollars and in fermentation 842 million US dollars. In Germany, alternative proteins received a drawback, locking in at 53 million euros, which is 41 % less than previously. This investment trend, however, can a) be observed across sectors, thus the trend is not specific to the cellag sector, and b) the German precision fermentation start-up Formo received the biggest ever series-A round in European 2021. Therefore, the sector faced an ambitious benchmark for 2022.

Investments partly stem from the conventional meat industry. Apart from InFamily Foods, already mentioned above, the German meat and plant-based meat producer Rügenwalder Mühle partnered up with the Swiss start-up Mirai Foods to produce a hybrid product (a plant-based burger with cultivated fat) and funded feasibility studies for the first cultivated meat farm planned by RESPECTfarms.

PHW, headquartered in Lower Saxony, Germany, established their alternative protein business unit in 2018 and has since then invested in the pioneer Supermeat based in Tel Aviv, as well as Redefine Meat, another Israeli company which focuses on plant-based alternative protein products. Investments were also made in the US-based LiveKindly, and Gathered Foods, both focused on plant-based products. To date, there are no investments in German start-ups in the alternative protein sector.

Funds

FoodLabs from Berlin was founded in 2016 and finances early-stage start-ups working on sustainable foods. Among other food technologies, they have invested into the German precision fermentation start-up Formo. Next to FoodsLabs, Good Seed Ventures from Rheine invested into Formo, as well.

Other German funds that have not necessarily funded (German) cellag start-ups but reflect potential future cellag investments are: Purple Orange Ventures from Berlin, Green Generation Fund from Berlin, Zintinus from Berlin, and Oyster Bay from Hamburg.

Finally, the German accelerator program for startups ProVeg Incubator is open to start-ups worldwide that work on plant-based, fermented, and cultivated foods. Regarding German cellag corporates, they so far funded start-ups such as Formo or Cultimate Foods.

Public

The Federal Ministry of Education and Research (BMBF) promotes two projects researching cultivated meat: the research project of Innocent Meat and the University of Rostock for scaling up production with € 500,000 as well as Germany’s first research consortium CELLZERO Meat, which aims to solve three big challenges of the sector – FBS, antibiotics for cell media and genetic engineering.

Political Landscape in Germany

The development of new economic sectors is usually a phase that is advanced by public investments. This is primarily because of the high investment risk for the private sector. Private investment enters when fundamental questions and obstacles have been answered or overcome.

In Germany, the support of alternative proteins is specifically mentioned in the coalition agreement: "We are strengthening plant-based alternatives and advocating for the approval of innovations such as alternative protein sources and meat substitutes in the EU", coalition agreement, signed by the Social Democrats, the Green Party, and the Liberals [directly translated into English]. Cellag is part of alternative proteins at large. However, since the formation of this coalition in December 2021 and although basic research for the whole cellag field is needed, there has not been significant advancement of cellag in Germany or public support for this industry.

Need for political support

Having alternative proteins in the coalition agreement is a first step to publicly support this industry. What are the political challenges withholding the industry to flourish? What is specifically needed in the German political landscape to happen? Three main necessary action points can be outlined when it comes to the German political landscape for cellag.

Funding for Open Access Research

Public funding for the cellag industry in Germany is scarce (especially for cultivated seafood and precision fermentation) and lacks a long-term strategy to transform the German food system. There are several programs to promote alternative proteins, but for the size of Germany and the amount of research that is still needed, the funds are too small, too rare, and unstrategic.

One call to promote cellag in Germany is the research call to promote innovation, the so-called “Programm zur Innovationsförderung”, executed by the German ministry of agriculture and nutrition from November 2021. From the 43 projects that applied for a funding amount of 41.3 million EUR, only eight million EUR are planned for alternative proteins as a whole. Further, the call was delayed for several months, which reduced the planning certainty of the companies that had applied for funding. The call exemplarily shows the need for funding into alternative proteins, and cellag specifically, which cannot be covered with the current German public funding.

An example for a more coherent strategy is the Netherlands that is funding cellag specifically with 60 Mio. EUR to build up a Dutch ecosystem. In comparison to European public funds as in the Netherlands (with the 60 Mio. into cellag only), Denmark (200 Mio. EUR on alternative proteins) or Norway (10 Mio. EUR into cellag only), Germany would have to expand its public funds on cellag massively. Considering the German population size with the Dutch one, Germany would have to fund cellag with around 300 Mio. EUR to keep up with the neighbors’ funds.

Regulatory support

Germany could play a vital role in shaping the regulatory system in Europe in a positive way, making it more transparent, supportive and reliable, especially due to its size. Key challenges and demands of German start-ups include improved guidance and checklists as well as improved and closer communication between authorities and start-ups. Although there were no milestones in the EU regarding regulatory approvals, there was a panel discussion organized on cultivated meat in the European Parliament. Stakeholders such as Mosa Meat, GFI Europe or CE Delft were present and provided information on the status-quo and benefits of cultivated meat. As more and better communication structures are needed, Germany could play a more active role in organizing these events.

Further, the regulatory approval process for cellag, which falls under EU Novel Foods regulation, contains a political process where representatives of each member state vote in favor or against the regulatory approval of a product. 55% of the countries that entail 65% of the European population size must be in favor of approval. This shows the vital role Germany, as the motor of the European economy and population, can play in facilitating the regulatory approval process of cellag products within the European market.

Fair competition

Like in other European countries, the tax system in Germany favors animal-products over animal-free products, creating disadvantages in open and free markets. As for the need to eradicate these unfair conditions for the plant-based sector, the future tax system would either have to treat all animal and animal-free protein products the same or consider the ecological implications and costs of a product to make the German tax system more just.

Universities in Germany

The one thing Germany stands out with is the creation of the first professorship ever in cellular agriculture. Prof. Dr. Marius Henkel got hold of this position in September 2022, building on this professorship at the Technical University of Munich (TUM) School of Life Sciences. Within this professorship, Prof. Dr. Henkel views cellag as the process of replacing conventionally produced animal agricultural products with biotechnological methods, including cultured meat as well as precision fermentation. The research will focus on bringing together various disciplines, including biology, engineering and food technology to first combat difficulties in today’s bio-scaffolding processes, which are necessary for a growing tissue to be supplied with sufficient nutrients. The plan is to generate mathematical-physical models to enable calculations on how far the nutrients can penetrate the tissue. These models will be linked with artificial intelligence to predict the best conditions for cultured meat to grow.

While the TUM supports Germany-based research in cellag with a professorship, there are further universities playing their part in the cellag space.

The Hochschule Reutlingen is home of Prof. Dr. Petra Kluger’s lab with various projects focusing on cultivated meat. Projects include the research on sustainable meat, taking into account economic and environmental aspects of cultivated meat production, the upscaling on speroid-based meat production to combat problems faced through scalability of the current processes, and serum-free bioprinted meat, to investigate how cultivated meat can be produced without the use of FBS.

At the University of Vechta, Prof. Dr. Lin-Hi is professor of economics and ethics. Here, research focuses include the nutrition of the future, with a special focus on cultivated meat, being a strong advocate of cellag from an ethical and economic point of view.

Dr. Florian Fiebelkorn at the University of Osnabrück highlights the potential of cultured meat from the perspective of a biology didactician. With his research focused on investigating the influences of knowledge and attitudes on sustainable diets and biodiversity conservation, cellag-based publications are included in his and his team’s portfolio to address consumer acceptance of cultured meat.

Further stakeholders at universities in Germany contribute to the cellag research sector. Stefan Wahlen is Professor of sociology of nutrition at the Justus Liebig University of Giessen and also has a say in the social component of cultured meat production. At the Technical University of Berlin, research on cultured meat is included with the focus on scaffolding and structuring. One project comprises cellular agriculture and 3D bioprinting. The University of Veterinary Medicine Hannover (TiHo) hosts the research institution WING (Science and Innovation for Sustainable Poultry Management), which conducted a survey on cultivated meat to support a project of French scientists who want to find out whether consumers worldwide would include cultivated meat in their diet.

Overall, research is still a great bottleneck to progress in the cellag sector, and Germany is providing its fair share to support this movement.

Civil Society in Germany

Several civil society organizations are actively supporting and providing information on cellular agriculture. CellAg Germany is the non-profit that solely focuses on accelerating the cellag space in German-speaking Europe. GFI Europe and ProVeg are both active on cellag and other alternative proteins. Bio Deutschland and BalPro (Verband für alternative Proteinquellen) are associations representing companies from the space. And finally, NABU (Naturschutzbund Deutschland) is starting a project aiming to enable dialogue and exchange between environmental organizations in Germany on food innovation including cellag.

About CellAg Germany

CellAg Deutschland e.V. is the platform for cellular agriculture in Germany and German-speaking countries in Europe. It is the only German non-profit organization that is solely covering the topic of cellular agriculture. CellAg Germany acts independently as it is not funded by corporates. CellAg Germany aims at informing and connecting academia, politics, industry, and society around the topic of cellular agriculture. More information on the website.

Stay connected with CellAgri

Join our mailing list to receive the latest news and updates weekly from the cellular agriculture industry. Your information will not be shared.